Welcome to our company

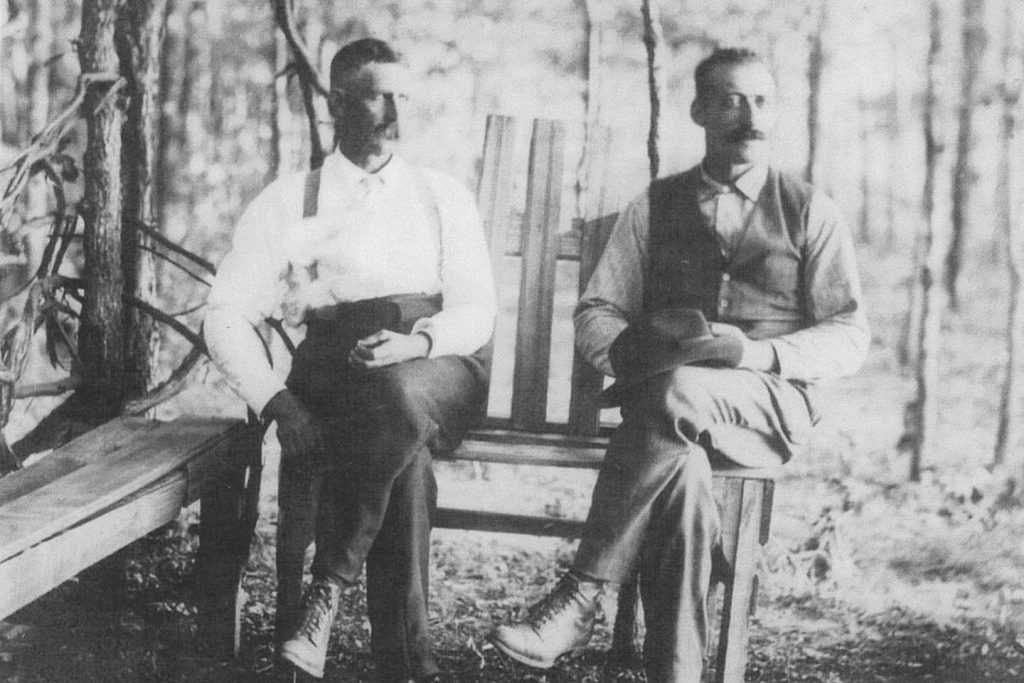

Located minutes away from Lake Michigan’s pristine Southwest Lakeshore in South Haven, Michigan. The lake protects the farmland that was founded in 1899 by Herschel Adkin, one of the original pioneers of the Southwest Michigan Lakeshore area emigrating from England via Canada. Starting out as a peach grower, Herschel started with 240 acres and 5 employees working the land. Within a few years, Herschel became one of the most successful peach growers in Southern Michigan.

Herschel’s son, Roy, took over the farm adding cherries, pears, and apples but struggled during the Great Depression. Through perseverance Roy was able to keep the farm profitable enough to pass it along to his son, Glenn, in the early 1950’s. Glenn was a prolific vegetable and tree fruit farmer. The farm harvested 500 acres of cauliflower and 500 acres of tree fruit. In 1958, Glenn planted the first blueberry bushes at the farm and quickly found that the rich soil and mild lakeshore climate was perfect for his new crop.

By the early 1960s, Glenn increased the blueberry acreage with the advent of the mechanized harvester. In 1965, the farm became incorporated and was re-named Adkin Blue Ribbon Packing Company, Inc. As blueberries grew in popularity, the farm flourished and Glenn built the first commercial blueberry packing line in the State of Michigan.

Glenn passed the farm on to his son Randall, who saw a continued opportunity with blueberries and planted additional acreage phasing out fruit trees. By 1981, Randall “picked” the last cherry tree by bulldozer, paving the way to the farm’s future success.

Randall integrated a state of the art sorter and packing machine to help increase frozen and fresh blueberry production. As blueberry harvest increased, Randall noticed the need to make sure his customers were receiving the safest fruit available from his farm and took the initiative in 1993 to become AIB (American Institute of Baking) certified, receiving and maintaining an excellent rating.

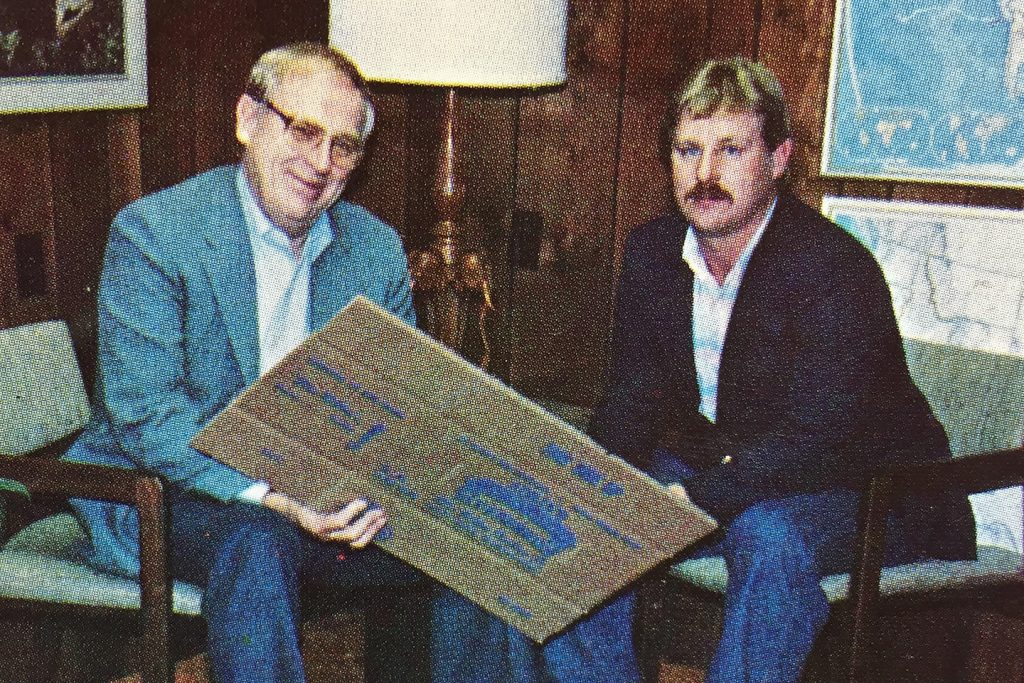

Also in 1993, Randall looked into additional ways to distribute the farm’s ever-expanding blueberry crop and became the first blueberry shareholder at North Bay Produce, Inc., a Michigan based cooperative of grower/shippers that distribute fresh produce throughout the world. Randall was an influential member of the North Bay Produce board of directors for over 20 years.

In the early 2000’s Randall brought his son, Bart into the family business. Bart has been instrumental in increasing the technological protocol of the processing line adding laser color sorters and incorporating controlled atmosphere packaging for storage of harvested berries. With his keen eye for future breakthroughs in farming, harvesting, packaging, and fruit storage, Bart will successfully bring the farm into the next century.

In 2014, the GFSI (Global Food Safety Initiative) scheme was added to their safety certifications along with HACCP (Hazard Analysis and Critical Control Points), GMP (Good Manufacturing Practices) and GAP (Good Agricultural Practices) to make sure all employees are picking, packing, and storing the safest fruit possible.